High Voltage Cable Pulling

FMI has successfully completed several underground transmission cable pull projects, such as a 242kv circuit in Victoria, BC, a 115kv Parallel circuit in Winnipeg, MB and a 138kv circuit in Kitimat, BC.

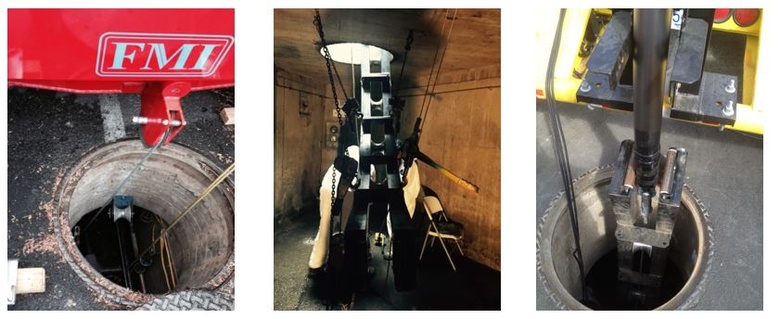

To successfully complete this work, FMI invested in cable pulling equipment. FMI uses a self contained transportation and unloading system that includes:

- Bagela winch

- Under-roller system for the large cable reels

- Variable frequency drive ball rollers for pull-through type man holes.

FMI understood the importance of being efficient and compact for moving the set up from location to location. Also, as many of these projects are located in major cities, it is important to have the least impact to surrounding businesses and homes. Having the smallest foot print possible and emitting the least amount of noise was of the utmost importance. FMI and our own inhouse fabricating company CCL, designed our custom cable pulling trailer. This trailer contains under rollers, a 3-phase generator to run the equipment and a custom radius cable shive to guide the cable into the manhole.

While this equipment is a great asset, FMI also needed a team with high standards to run the equipment and perform these projects. FMI built a team from our internal forces. We also invested time to set up a practice pull at our head office facility to get our forces up to speed on the equipment. Once this was completed, we brought our client to our facility to witness our set up in action to give them the confidence that we would be able to complete our first large scale pull. From this point on our team has continued to develop after completing numerous projects.